Background and calendar

The history of our Foundry goes back to the beginning of the 1970s when the Predom Zelmer Household Power Appliances Manufacturing Plants established their own foundry department. It was when the first two casting machines were purchased and manufacturing of aluminium and zinc castings began. The machine stock has been expanded since 1973 with a dynamic growth of the foundry plant. Since December the 5th 2006 the company operates as an independent business entity under the name Meta-Zel Sp. z o.o. Pressure Casting Foundry (Odlewnia Ciśnieniowa Meta-Zel Sp. z o.o.).

The beginnings of the activity as a casting department of Mechanised Household Equipment Works Predom Zelmer

History of the foundry started more than 40 years ago. At the beginning in Mechanised Household Equipment Works Predom Zelmer was created casting department. The two cold chamber die-casting machines were purchased and the production of aluminium AK-11 and zinc Z-41 alloy die castings started. Castings were mainly for PREDOM ZELMER for the vacuum cleaner and food mixer motors.

Start-up of the melting center provided with the induction furnaces

Since 1976 started up the melting center provided with the medium frequency induction furnaces. The crucible furnaces PET were used only for maintain temperature of the metal for production.

Introduction of the new technology of for cleaning and machining of the castings

Between 1977 and 1979 company introduced new technology for cleaning and machining of the castings. The trimming die for removing gating systems, multi-spindle drill heads and threading heads were implemented.

Start – up of the metallurgical laboratory

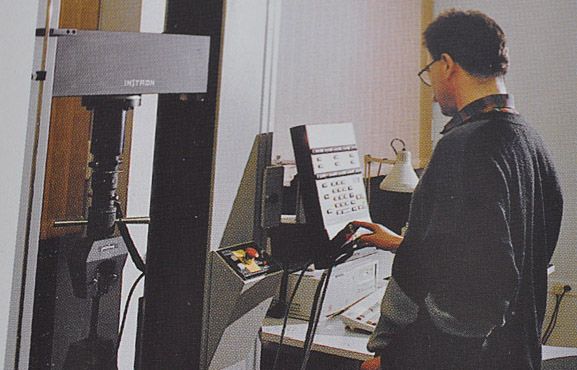

The year 1982 was very important for the foundry. The machine park was renovated and upgraded. The components from aluminium alloy such as AK-132, AG-10, Z-41, ALSi 12S i A-1 were in the production. The components differed in the degree of complexity, for example, castings with the metal inserts or external threads. Significant meaning for the materials management had a start–up of the metallurgical laboratory. Initially, it only performed resistance properties tests and metallography. The scope of research opportunities greatly increased when, with the Institution of Precision Mechanics ran spectrometer to study the chemical composition of the alloys . The period is characterized by the cooperation with European companies and export of casting to Western Europe. In such form, the foundry functioned without major changes up to mid 90ies of the XX century.

Creation of the separate company under the name of Odlewnia Ciśnieniowa META-ZEL Sp. z o. o.

At the end of 2006, Odlewnia Ciśnieniowa META-ZEL Sp z. o. o began operating as an independent enterprise. Soon after, the management introduced Quality Management and Industrial Safety Systems. In 2007, the company obtained a permit to operate in Podkarpackie Science and Technology Park “AEROPOLIS”.

Development of cooperation with research and academic centers

From the beginning, the company has made contact with leading research centers and universities, which is reflected in the joint patents. Together with the Rzeszow University of Technology, Department of Casting and Welding are performed joint research projects. The company is also working with Foundry Research Institute from Cracow and AGH University of Science and Technology, Faculty of Non-Ferrous Metals.

Obtaining a grant from the Innovative Economy Operational Programme and start of the investment in Wola Cicha near Rzeszów

In 2008, the company obtained a grant from the Innovative Economy Operational Programme co-funded by the European Regional Development Fund, Action 4.4. New investments with high potential for innovation. New headquarters and modern production and storage hall was built in a special economical zone “Aeropolis” near Rzeszów. The project also allowed for the purchase of new casting machinery and measuring devices, which greatly increased the potential and capabilities of the foundry.

Completion of the new foundry and move headquarters to Wola Cicha near Rzeszów

At the beginning of 2012 ended the investment was completed and the company moved to new premises in the Wola Cicha near Rzeszów. Currently, the main challenge is to attract new customers, both at home and abroad, and maximize the use of available capacity.